Why Bidirectional OTDR (Optical Time-Domain Reflectometer) Testing Is Essential for Accurate Fiber Certification

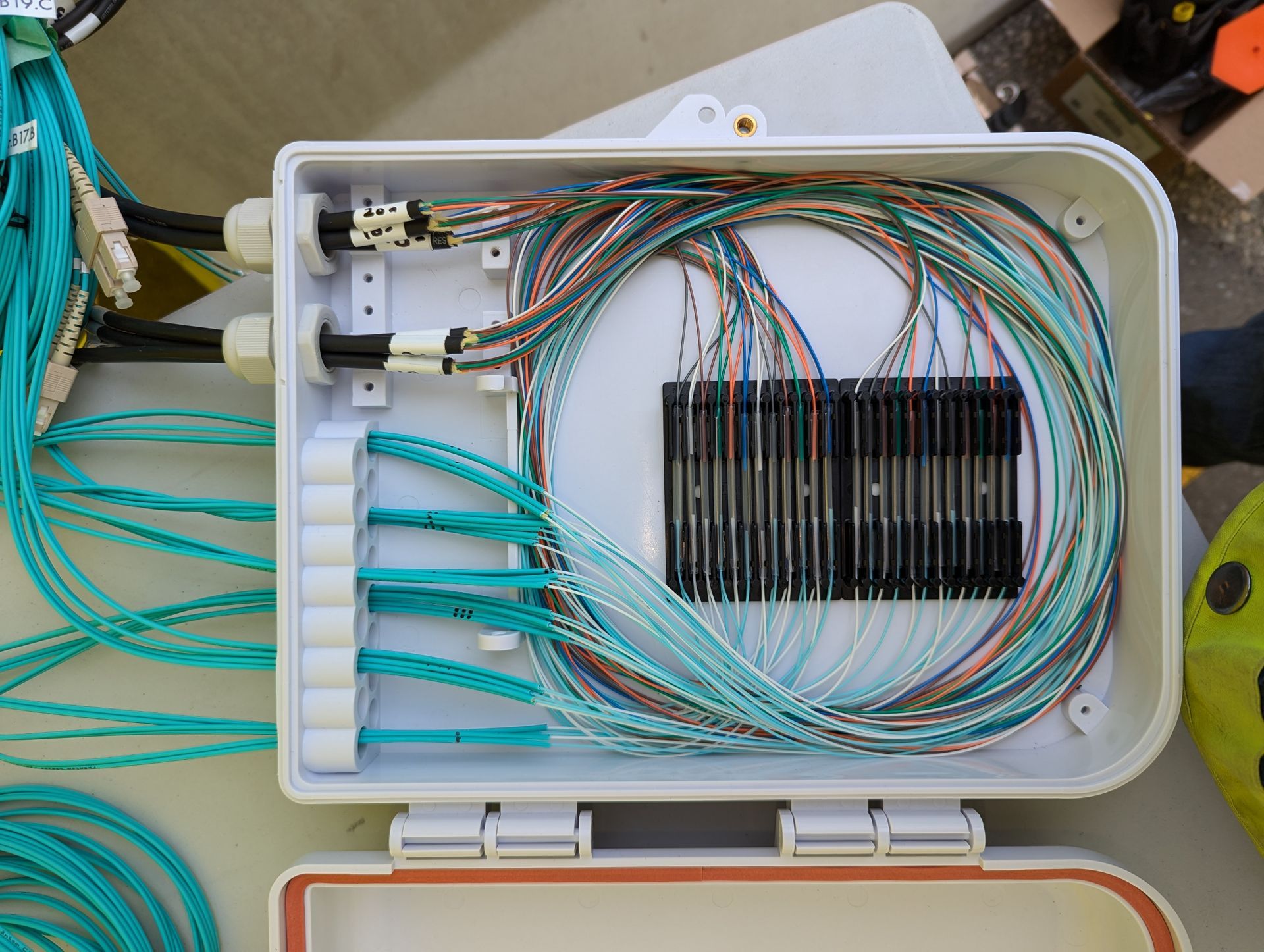

When it comes to building,repairing or upgrading high-performance fiber optic networks,

fusion splicing stands out as the gold standard. Whether you're working on a large-scale fiber optic backbone installation or a last-mile commercial install, the quality, durability, and long-term cost-effectiveness of fusion splicing make it the superior choice over alternatives like mechanical connectors.

What Is Bidirectional OTDR Testing?

A traditional OTDR test measures fiber loss, splices, and reflections from one end of the fiber. But fibers aren't perfectly uniform — small variations in core geometry, splices, or connector reflections can skew results when viewed only from one side.

Bidirectional OTDR testing means measuring the fiber from both ends and averaging the results. This provides a true picture of:

- Splice loss

- Connector loss

- Overall fiber link loss

Looking for expert support with fiber testing? Explore our

Testing & Certification Services to ensure your network meets Tier 1 and Tier 2 standards.

Why Single Ended Testing Falls Short?

When testing from only one side:

- A splice can appear better or worse than it actually is, depending on local fiber mode field diameter mismatch.

- Loss measurements may be asymmetric, resulting in inaccurate certification reports.

- In critical long-haul or high-speed applications, these discrepancies can cause unexpected performance drops.

In short, single-ended OTDR testing can compromise fiber certification accuracy.

Advantages of Bidirectional Testing

| Benefit | Explanation |

|---|---|

| True splice loss measurement | Accurately determines actual losses by averaging direction-dependent effects. |

| Accurate total link loss | Avoids under- or overestimating attenuation. |

| Meets certification standards | Required by ISO/IEC and many carrier-grade specifications. |

| Reduces future troubleshooting | Prevents disputes or warranty claims over fiber quality. |

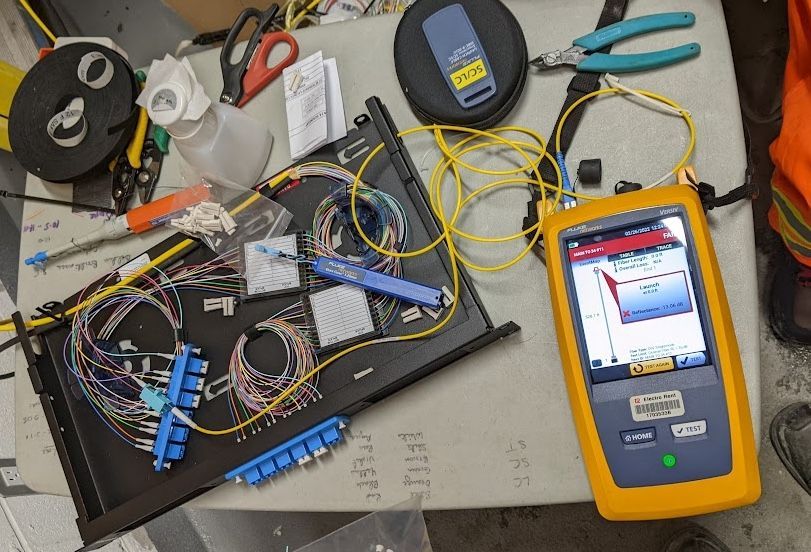

How to Perform Bidirectional OTDR Testing

- Test from one end using launch and receive cables.

- Record trace, note events and overall link loss.

- Reverse test setup.

- Move OTDR to the opposite end.

- Swap launch and receive cables.

- Average event losses - Use software or manual calculation to average each splice/connector loss.

- Document both traces - Save raw source files, plus averaged final report.

Not sure if your project needs full bidirectional testing? Our

Network Consulting Services can guide you through the best practices for accurate certification and long-term reliability.

Standards That Require It

- TIA-568-D.3 and ISO/IEC 14763-3:2014(E): Recommend bidirectional testing for full Tier 2 certification.

- Enterprise & Carrier-grade projects (e.g., Banks, Data Centers, Bell, Rogers, Metrolinx, Hydro etc.): typically mandate bidirectional OTDR for backbone and access splices.

Real-World Example

On a recent commercial backbone project in downtown Toronto, FibreGuy engineers, testing as a third-party tester, found an initial splice loss that appeared higher from one side. After bi-directional testing and a thorough cleaning and reseating, the true average loss was much lower—meeting certification limits and preventing unnecessary rework.

SME Perspective

In fiber, what you don’t measure can hurt you. We always perform bidirectional tests on critical links to ensure every splice is truly compliant and no surprises crop up later.

Conclusion

Bidirectional OTDR testing isn’t just an extra step — it’s a required step for accurate fiber certification. By verifying each link from both directions, you:

- Ensure compliance with global standards.

- Deliver reliable, long-lasting network performance.

- Avoid costly troubleshooting and callbacks.

FibreGuy offers certified, accurate fiber installations — done right the first time.