Why Fusion Splicing Is the Best Choice for Fiber Installations

When it comes to building,repairing or upgrading high-performance fiber optic networks,

fusion splicing stands out as the gold standard. Whether you're working on a large-scale fiber optic backbone installation or a last-mile commercial install, the quality, durability, and long-term cost-effectiveness of fusion splicing make it the superior choice over alternatives like mechanical connectors.

What Is Fusion Splicing?

Fusion splicing is the process of permanently joining two optical fibers by melting their ends together using an electric arc. The result is a single, continuous optical path with minimal signal loss and superior mechanical strength.

A properly done fusion splice has essentially zero reflection and minimal loss, making it ideal for high-speed, high-bandwidth, high-performance fiber optic networks.

Advantages of Fusion Splicing

| Benefit | Why It Matters |

|---|---|

| Low Insertion Loss | Typical loss is ≤ 0.02 dB—essential for high-speed or long-haul fiber optic networks. |

| No Reflections | Eliminates Fresnel reflections that degrade signal integrity, especially in singlemode fiber links. |

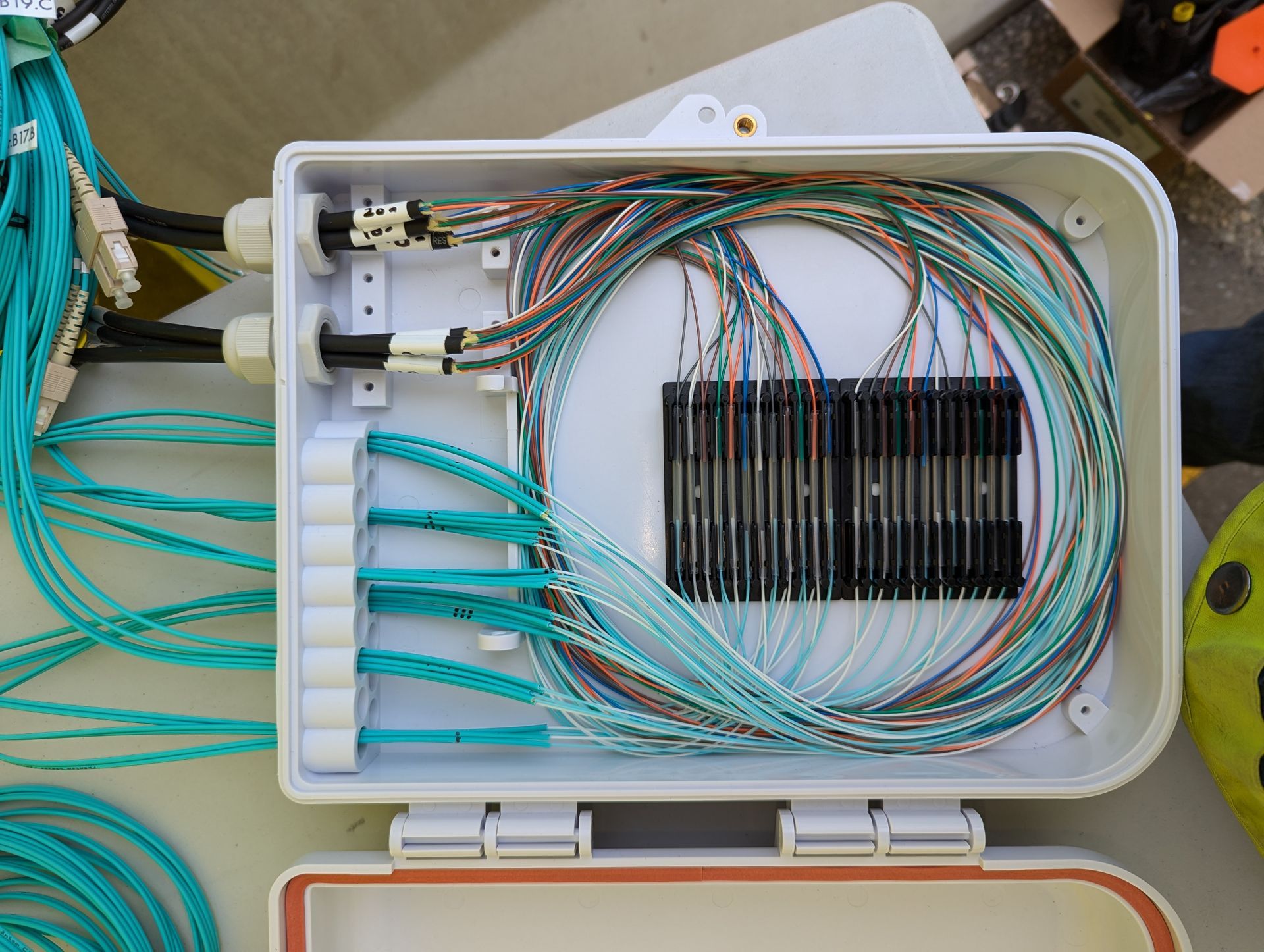

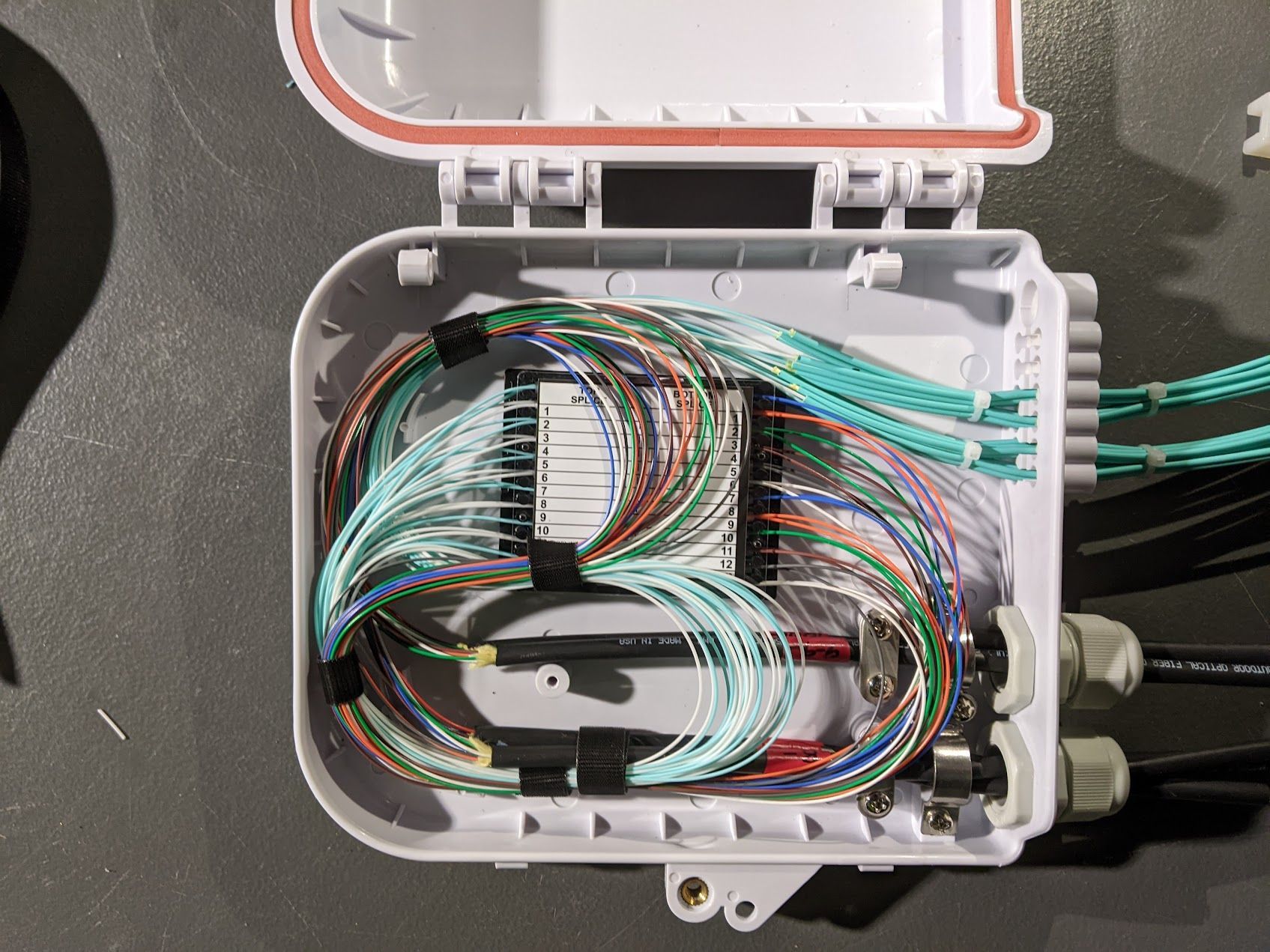

| Mechanical Durability | Splices are immune to vibrations, moisture, and temperature swings when properly sleeved. |

| Permanent Reliability | Permanent Reliability Unlike mechanical splices, fusion splices don’t rely on gel or alignment clips that can degrade. |

| Compact Profile | Ideal for fiber trays, closures, or panels—splices are slimmer than mechanical connectors. |

Why Not Mechanical Splicing?

While mechanical splicing has its place in temporary or low-volume fiber repairs, it has several drawbacks:

- Losses between 0.2 and 0.75 dB—far higher than fusion.

- Susceptible to failure from dirt, misalignment, or gel drying out.

- More expensive per splice over time ($5–30 per connector vs <$2 for fusion sleeves).

Mechanical splices are fast, but they sacrifice

performance and long-term stability—especially in mission-critical links.

Use Cases Where Fusion Wins

- Telecom & FTTH (Fiber to the Home): Required to maintain low signal loss across kilometers of fiber.

- Enterprise & Campus Networks: Stability and consistency across high-count splices.

- Industrial or Outdoor Installations: Fusion splices hold up to wind, temperature, and vibration.

- Permanent

Repairs: Clean, certified splices that pass Tier 1 and Tier 2 testing (OLTS + OTDR).

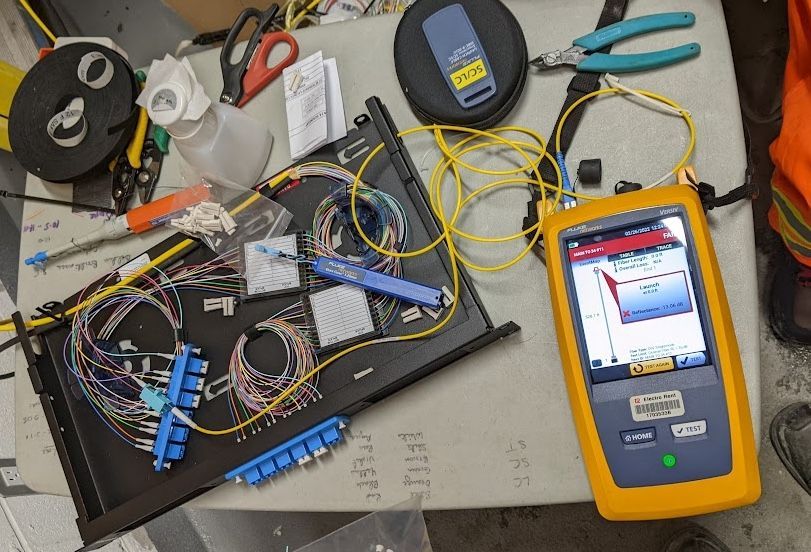

Tools of the Trade

Fusion splicing requires:

- Fusion Splicer: Core-alignment models offer best precision.

- Cleave Tool: Clean, perpendicular cuts are critical.

- Splice Sleeves: Heat-shrink tubes with metal strength members for environmental protection.

- Oven: Often integrated in the splicer to shrink protective sleeves.

FibreGuy’s team uses only core-alignment splicers from industry leaders to ensure every splice meets telecom-grade standards.

Real World Proof

In controlled tests:

- Fusion splices showed ~0.01 to 0.02 dB loss

- Mechanical splices averaged

0.3 to 0.75 dB and higher failure rates under tension, bending, or thermal cycling

SME Perspective: Why FibreGuy Recommends Fusion

“We’ve seen it time and again—mechanical connectors fail under pressure, literally. Fusion splicing, when done correctly, is nearly invisible to light. That’s what our clients expect, and that’s what we deliver.”

—

Senior FibreGuy Technician

Fusion splicing isn’t just a technology, it’s a commitment to quality and long-term reliability. Discover our

fiber optic splicing services for flawless, long-lasting connections.

Long-Term ROI

- Lower per-splice cost when doing volume.

- Less maintenance, fewer re-calls.

- Higher customer satisfaction due to consistent signal quality.

Even though fusion equipment requires up-front investment, it

pays for itself quickly with the number of satisfied clients the first time, every time. Our experts provide

network consultancy solutions tailored to your project. Get strategic guidance from our fiber network consultants to future-proof your infrastructure.

Conclusion

When quality, performance, and longevity matter, fusion splicing is the best choice. It’s the industry standard for a reason:

- Lower loss

- Stronger joints

- Fewer callbacks

- Future-proof builds

Choose fusion splicing. Choose reliability. Choose FibreGuy.